What is a Reinforced Thermoplastic Pipe (RTP) or Flexible Composite Pipe (FCP)?

Flexible Composite Pipes (FCP) are the next generation in high pressure pipelines. The SoluForce system is corrosion-, scaling and maintenance free, and suitable for a wide range of applications, making it the 21st century pipeline solution. SoluForce is the technological leader in manufacturing Spoolable Flexible Composite Pipes (FCP), also known as Reinforced Thermoplastic Pipes (RTP).

Names: RTP or FCP?

RTPs were first developed and produced in long-lengths by Pipelife Nederland B.V. in the year 1998. The basis of this 'Long-Length Reinforced Thermoplastic Pipe' (LLRTP) was (and still is) a modified version of a flexible thermoplastic pipe, which was already produced by Pipelife since the 1960's. To be able to withstand high pressures, a reinforcement layer was added to the flexible thermoplastic pipe. Hence the name 'Reinforced Thermoplastic Pipe', or RTP.

Due to the advantages of RTP, more and more major oil and gas companies and operators started to replace their steel pipelines with this new technology. This also meant that additional RTP products were developed and produced. These new products used various ways to reinforce the pipe. With the growing number of pipe types, producers and users, certification needed to be implemented to include all versions of reinforcement. Therefore, it was decided by the major industry associations to change the name from 'Reinforced Thermoplastic Pipe' to a more general 'Flexible Composite Pipe' (FCP) in the year 2010.

Flexible Composite Pipes are sometimes also called: "Flexible Flowline", "Flexible Linepipe", "Spoolable Reinforced Plastic Linepipe", "Flexible Reinforced Pipe", "Reinforced Line Pipe" or "Spoolable Composites". For offshore use other names include "Offshore Flexibles" or "Flexible Umbilical Risers".

Usage of Flexible Composite Pipes

Although the SoluForce FCP was originally developed for the oil and gas industry, they are also used for: domestic gas, domestic water, mining, CO2 and hydrogen applications.

Because of the many unique benefits of the SoluForce system, it is used in all kinds of environments, from the extremely high temperatures and UV radiation of the Kuwaiti desert, to near 100% humidity of the Indonesian Jungle, to the west coast of Africa under 80 meters of water.

FCP properties

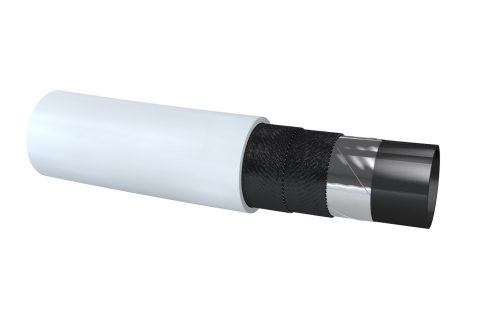

A FCP is generally composed of several layers. For example, SoluForce pipes are built out of three layers: a liner pipe made from HDPE (High-density Polyethylene), a reinforcement layer and a HDPE outer cover layer. SoluForce Gas Tight features an additional aluminum layer to prevent permeation of light components.

Compared to other RTP suppliers, the SoluForce FCP system has the additional benefit of being completely bonded. This means that all the layers are bonded together to form one strong unit, instead of all layers being loosely stacked on top of each other. It can even be included with a non-metallic (i.e. non corrosive) fitting system. This enables the SoluForce system to have unique features versus conventional steel or carbon steel pipe lines and other FCP versions in the area of reliability, corrosion resistance, flexibility, installation speed and re-usability.

The SoluForce FCP system meets and is certified against international standards for water, hydrocarbon and gas transportation. The SoluForce pipe system has design pressures of up to 450 bar/ 6527 psi, and can be used for both onshore and offshore applications.

The layers of SoluForce FCP

1. Cover Layer

All SoluForce solutions feature our signature white cover layer. This layer is not load bearing but engineered to protect the pipe against outside influences like stones, sand, water, etc. Furthermore, this layer is UV stabilized to ensure it does not degrade from UV rays.

2. Reinforcement layer

Synthetic Fibre Reinforcement

The SoluForce Light and Classic systems use a synthetic fibre reinforcement. Because these SoluForce systems are fully non-metallic, they are an ideal solution for even the toughest applications and extremely corrosive fluids such as sour oil service without restrictions regarding H2S and CO2 content.

High Strength Steel Wire Reinforcement

The SoluForce Heavy system is reinforced with a high strength steel wire and is specially developed for extremely high pressure. Just like all the other SoluForce solutions, this system is resistant to (strong) inorganics acids like HCI, H2SO4 and (strong) alkaline materials, including NaOH, KOH and NH3 solutions. The CO2 content in the fluid can be very high, up to 7% in the gas phase.

3. Gas Tight layer

SoluForce also offers Gas Tight (GT) types of the Classic and Heavy systems. This adds an additional layer of aluminum to the pipe. This results in the industry's only true permeation tight FCP system which enables transportation of gasses and fluids in a completely non-permeating manner without venting or any other special treatment of the pipe.

4. Liner Pipe

All SoluForce solutions feature a flexible HDPE liner pipe that can withstand all fluids and gasses found in oil and gas applications, including: H2S, CO2, strong inorganic acids like HCI and H2SO4, strong alkaline materials like NaOH, KOH and NH2. The liner pipe is 100% corrosion free. Due to the smooth inside surface it is also 100% scaling free and has significantly less flow resistance than steel pipes. For SoluForce High Temperature, the liner pipe is specifically engineered to withstand actual operating temperatures of up to 85°C/ 185°F. A level of performance unmatched by any other FCP available today.

Contact us

Do you have questions? Contact us via contact form or chat! Our experts will get in touch with you as soon as possible