Hydrocarbon Transportation

Corrosion & Scaling-Free Flexible Oil Pipelines & High-Pressure Gas Pipe

Whether you need to deploy a network in physically challenging terrain, move highly corrosive liquids at high pressure, or both, SoluForce pipeline systems have your needs covered.

Why use SoluForce flexible pipe system?

Our hydrocarbon pipes and pipes for high-pressure water injection lines feature Aramid or high-strength steel wire reinforcement, high-density polyethylene liners and non-metallic fittings, ensuring maximum durability for the entire system.

Pushing the boundaries even further, our SoluForce Heavy HT (High Temperature) has design temperatures of up to 105°C/225ºF — a level of performance unmatched by any other flexible composite pipe available today. SoluForce GT (Gas Tight) pipes have been specially developed for high-pressure gas applications and completely eliminate gas permeation from substances including H2S and BTX. SoluForce GT is the industry's only true permeation-tight high-pressure flexible pipe on the market today.

All SoluForce flexible composite pipeline systems can use metal-free fittings, couplings and connectors. Our pipeline systems are, therefore, resistant to all chemicals involved in oil and gas production and extremely sour environments, including:

- H2S

- CO2

- Strong inorganic acids like HCl and H2SO4

- Strong alkaline materials, including NaOH, KOH and NH2 solutions

- Anti-corrosion additives

- Mineral salts

Pipe Types

SoluForce Flexible Composite Pipe (FCP, also known as Reinforced Thermoplastic Pipe or RTP) solutions are comprehensive yet economical. For example, you can opt for pipes-and-fittings only or extend this with a range of services and support. With up to 400 meter of pipe per coil and installation speeds of up to 2 KM a day, SoluForce has proven itself as the go to solution for quick and economical deployment of long lenght pipelines. Furthermore, a minimal ROW and installation crew is required to install the system.

Our services include installation equipment for rent or purchase and training international and local workforces to use the SoluForce system — all so you can safely speed up installation and reduce your labor needs. We can also assist with project management and help you find the right people for your project. Or any combination of the above.

Because the SoluForce system can be completely non-metallic, they are both scaling and corrosion free. All SoluForce pipe systems have a smooth bore, ensuring a much lower flow resistance and improved flow capacity compared to comparable diameters of other pipe systems. Moreover, their resistance to third-party interference and earthquakes has been extensively proven and verified, making them ideal in remote locations.

All SoluForce solutions comply with international standards (including API and ISO). Visit our track record page for more information on various SoluForce applications.

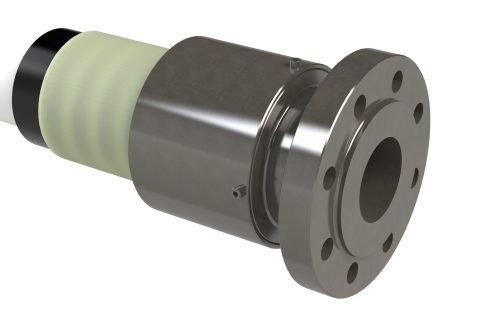

Fitting Solutions

The SoluForce system includes a variaty of fitting solutions. These all allow for easy hook up of the SoluForce system to existing infrastructure. All fitting systems are extensively tested, certified and have proven themselves in many onshore applications. With the electrofusion and single swage fitting solutions, the fluids or gasses never come into contact with the metal parts of the fitting system. This results in a completely corrosion and scaling free system.

For pressures higher than 150 bar/ 2175 psi, the double swage fitting is the system of choice. Most fittings can be disconnected easily to allow for easy relocation of the pipeline.

Multiple flange ratings are available. All steel parts can be produced according to your material specifications.

Speak To Our Specialists

SoluForce Hydrocarbon Projects

Long life, non-metallic pipe systems

SoluForce high pressure flexible composite pipe systems significantly reduce CAPEX and completely eliminate OPEX, making them the perfect solution to improve operational efficieny.

Frequently Asked Questions

What function do gas and oil and pipelines perform?

Both oil and gas fields are connected by large pipe networks. Oil and gas flowlines are pipes that connect wellheads to a manifold (a junction where multiple pipes meet). From there, a gathering line moves crude oil or natural gas to a processing site or a transportation facility to turn into refined products for the petroleum or gas industries

How far do oil and gas pipelines have to travel?

Oil and gas flowlines often need to cover long distances, often over very difficult landscapes. Because SoluForce pipes are flexible, they can be utilized in extremely difficult terrain and harsh climates, including the jungles of central Sumatra in Indonesia, and the harsh deserts of northern Iraq-Kurdistan. Even in these hostile environments, engineers were able to lay 880m of pipework per day.

Why do gas and oil pipes need to withstand high pressure?

When moving crude oil, natural gas or other petroleum products through a pipeline network, high pressure is required to keep the liquids and gasses moving down the pipelines. Depending on the viscosity of the substance being pumped, pipelines often operate at constant pressures of over 1,500 to 2,000 psi (approx 100-140 bar). In some cases even higher pressures are used

How much oil can be pushed through a pipeline?

Oil is measured in units called barrels, which are just under 160 liters. A pipeline’s flow rate is therefore measured in ‘barrels per day’ or even ‘barrels per hour’, with oil traveling at speeds of around 5-13 kph (depending on the piping sizing). In the United States for example, the Gulf Coast oil field currently sends an average of1.5 million barrels of oil ashore per year.

As we move away from fossil fuel use, will oil and gas pipes be redundant?

The oil and gas industries are beginning to clean up their products as we move towards a zero-carbon future, and despite the advances we’ve already made in renewables, hydrocarbon fuels and their pipeline transports will be around for a long while yet.

In the case of natural gas, steps are already being taken to blend hydrogen into the supply, with some studies estimating that this could reduce CO2 output from homes and businesses by up to 6 million tonnes per year — the equivalent of taking 2.5 million cars off of the road.

What makes SoluForce pipes so durable?

Most oil and natural gas pipelines are made of steel, and as the networks of pipes age, they are prone to corrosion and scaling. It can be difficult to detect pitting and embrittlement in steel pipes, and without regular inspection and maintenance, there is a very real risk of failure and spillages.

SoluForce pipes are completely non-metallic and flexible (Flexible Composite Pipe), so they never corrode or scale and can be installed in rugged or difficult terrain without the worry that they will crack in the event of earthquakes or other extreme conditions.

What makes steel pipes prone to corrosion?

Aside from external environmental factors, (pressure and temperature) both natural gas and crude oil contain lots of impurities that can corrode steel pipes over time, including hydrogen sulfide (H2S), carbon dioxide (CO2) and free water, which acts as a catalyst. Corrosion inhibitors, protective coatings and cathodes can all be used to prevent pipe failure, but avoiding steel entirely using flexible composite pipes is the only way to guarantee a corrosion-free pipeline (without using inhibitors, coatings or cathodic protection).

Why choose SoluForce pipe systems for onshore oil and gas?

SoluForce systems have been in use since 2000 across a wide range of applications and in some of the world's harshest environments. Our products are extremely durable and high-quality, meeting or exceeding recognized international standards — perfect for moving highly corrosive liquids and gas under high pressure.

Are SoluForce pipes easy to install?

SoluForce pipe systems are easy to install compared to heavy steel pipes. A small crew can install long pipework lengths quickly and efficiently (up to 2 KM a day), even when working in harsh terrain or with limited space.

Our team of Technical Service Engineers can help with any installation support, even providing equipment such as our electrofusion machine. In addition, we offer training programs to local contractors and engineers through our SoluForce academy.

How are SoluForce pipes joined together?

SoluForce has a range of fitting systems to meet the needs of every application. When transporting corrosive chemicals, non-metallic fittings are used, with joints welded together using Electrofusion.

What applications are SoluForce pipes suitable for?

SoluForce pipe systems can be put to use in a wide range of on- and offshore applications, including oil and gas flow lines, multi-phase pipelines, high-pressure water injection pipelines, gas condensate, oil and gas gathering lines, domestic gas distribution, (jet) fuel transportation, LPG translortation and more. In addition, our flexible pipes can be uncoupled, re-spooled and used again, maximizing value and versatility.

How does SoluForce solve the challenges of steel pips?

There are may advantages to high pressure SoluForce Flexible Composite Pipes compared to steel alternatives, the most important are:

- 100% Corrosion-free

- Fast installation - more than 2 KM a day

- No scaling or corrosion - a smooth bore for a lower flow resistance and improved flow capacity

- Reusable - simply disconnect and load onto our coiling trailer

- Requires zero maintenance-free

- Design life of up to 50 years underground, and a 20 year surface lifespan

- 400-metre lengths per coil - quick delivery and installation of large quantities

- Extremely robust - highly resistant to shock from earthquakes and disruption from landslides or erosion

How does SoluForce compare to other RTP/FCP systems

There are may advantages of the SoluForce system compared to alternatives, the most important are:

- Track record - spanning more than 20 years, with more than 3.500KM installed around the world

- Gas Tight - the only fully Gas Tight high pressure Flexible Composite Pipe available on the market

- Fully bonded - bonded pipe structure providing strenght and reliability

- Fully certified - developed and produced in The Netherlands and fully certified according to multiple industry (and local) standards

- Local presence - worldwide local presence

- SoluForce Academy - train your international staff and deliver local-context training

- Easy installation - easy installation process with 100% traceability and reliable fitting system

- Easy logistics - up to 400 meters per coil and up to 3600 meters on one flat rack

Get In Touch

Callback

bew.jpg)

.jpg)

.jpg)